Students go sleepless to prepare for auto competitions

Eric Theobald, from the Formula SAE team, does some welding in “the cage,” an area of the Hall Building garage where the students work on their cars.

Photo by Andrew Dobrowolskyj

The Concordia chapter of the Society of Automotive Engineers (ConSAE) are pulling all-nighters this week, as they prepare for the annual blitz of inter-collegiate design competitions.

SAE member Mike Klein said the Formula team “basically stayed from Sunday night until they left for Pontiac, Michigan, on Tuesday night.”

They took turns sleeping two hours each in the back seat of the Futurecar, one of their other creations, in the Hall Building garage. The reason: the pistons were shot. New pistons had to be ordered and the engine remade at the last moment.

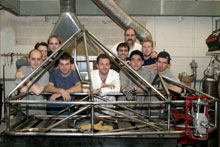

Some of the students in the Concordia branch of the Society of Automotive Engineers take time out from preparing their entry in the Formula competition. They work in “the cage,” a semi-enclosed area in a corner of the garage of the Hall Building. From left, Peter Silvano, Mike Klein, Evan Graham, Milan Vrana, William Chicoine, Samuel Lee, Eric Theobald, Frederick Guay, John Alfara and Dave Morgan.

Photo by Andrew Dobrowolskyj

The 10 students headed off for Michigan in their car on Tuesday night, hoping it holds together and performs well against about 120 cars from colleges and universities from around the world.

The SAE chapter takes part in four collegiate design competitions: Mini Baja, Formula SAE, Super Mileage and Aero Design. These contests, held around North America over the summer, provide engineering students with a chance to apply classroom theory to real-world problem solving.

Klein explained: “Usually, the teams specialize for their competitions, but if one of the Formula guys can weld better than one of the Mini Baja guys, then we'll help each other out.”

The students had a disappointment recently. They prepared to take part in the Eastern Mini Baja, held in Montreal May 6-8, but a sponsor let them down by not delivering parts in time. However, there’s another competition in June in Milwaukee, Wisconsin.

The Mini Baja project involves designing, manufacturing, and testing an off-road vehicle. The results are evaluated by a series of static and dynamic events, and an endurance race pitting all university groups against each other.

Designing the vehicle requires applied physics, manufacturing processes using computer-aided design (CAD), and machining skills. The testing phase requires troubleshooting and data collection work, and the team’s success is measured by how well the group manages to perform all these tasks efficiently.

The car must achieve high performance standards. It must also be low in cost, easy to maintain and reliable, and its marketability must include such factors as aesthetics, comfort and use of common parts.

The Supermileage project is teamwork-oriented, and involves the design, fabrication, and testing of a single-person, fuel-efficient vehicle. This vehicle has the potential to set world fuel economy records, thus increasing public awareness of fuel-efficient vehicles. This year, the competition is in June in Marshall, Michigan.

Aero Design teams are required to design, build, and test a radio-controlled airplane capable of carrying the most weight aloft, from a limited take-off distance. This month Concordia is participating in the West Aero Design competition in Fort Worth, Texas.

The SAE team gets financial support from the ECA [students association] and the Department of Mechanical and Industrial Engineering; some external sponsors donate money or parts. They’re especially grateful for the support of the Concordia machine shop.

SAE activities earn credit for some students via their “capstone” (required) courses, but Klein admitted that the effort they put in is way out of proportion to the academic credit they earn. They do it for love.

For more information, visit www.me.concordia.ca/~sae.